Okay, that's a bit pointed, but in fact one of the more common negative statements about simulation is that it's just "pretty colorful pictures" that don't bring any significant benefit.

What can be done to counter this? How to persuade? How best to explain it? That is also a good question with regard to the personal surroundings. As a simulation engineer, how do one answer the question of what you do for a living in a catchy and simple way?

The following sections are intended to provide an overview, but for the time being they will only be discussed very briefly here. Each individual section will be described more detailed in the coming months as a separate post. A general and hopefully informative series as a commitment to the simulation.

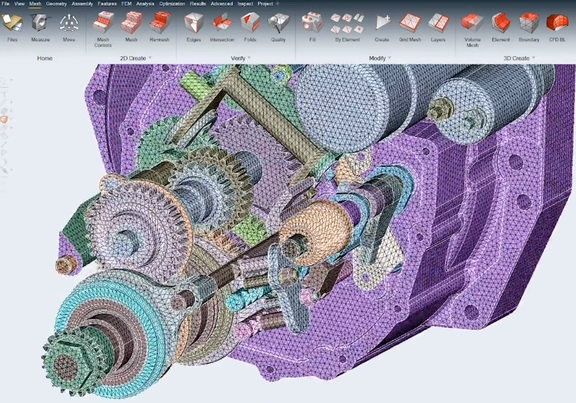

1. Simulation is varied

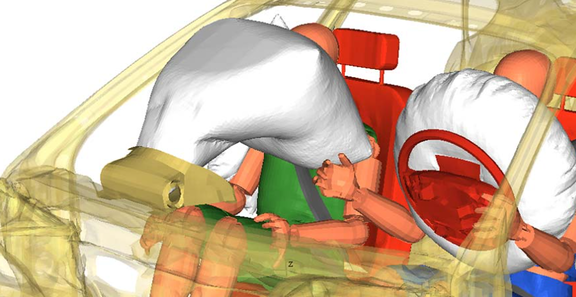

The areas of use for simulation are very numerous (e.g., finance, communication, entertainment, etc.). Typical simulations in engineering are static and dynamic strength calculations, manufacturing simulations, vibration analysis, heat transfer, etc. to name just a few examples. In these simulations, components from a wide variety of industrial fields are virtually modeled and tested. One of the catchiest examples to describe this is the crash test, which most people know and is therefore often used to explain what exactly one does as a simulation engineer (at least in the area of structural simulation).

2. Simulation has it´s reasons

Testing parts exclusively in the real world may not always be the right way for various reasons. Either it is simply not possible because, for example, the real component does not yet exist or cannot be observed in its built-in position, such as an inner part of the engine compartment in the previously mentioned example. In addition, the real test often is too complex and too expensive to repeat after every design change. On the other side, however, it must also be admitted that the simulation cannot replace the real test. For example, manufacturer specifications or legal limit values can usually only be validly verified by a real test.

3. Simulation is helpful

Simulation cannot replace testing, but it can identify a wide range of potential benefits. Especially with regard to function, economy and sustainability.

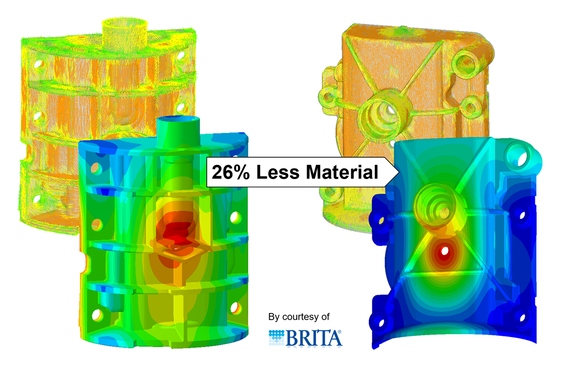

Let's take the development of a new component as an example. It has to fulfill one or more specific tasks and requirements. For example, it must be able to withstand a mechanical load and produced cost-effectively in large quantities.

Already in the concept or design phase, a suitable material has to be selected and the appropriate shape has to be designed so that the load is withstood and manufacturing is simple. Here, simulation helps in the most suitable way. The necessary load can be simulated and iterations with different materials are done with just a few clicks.

Taking this into account in advance development saves time and money, because expensive design loops based on prototype tests and subsequent changes are not economically reasonable. The design is chosen in such a way that the components are manufactured in the best possible way and require as minimal material as possible, and is therefore much more effective and sustainable than over-sized too heavy components.

4. Simulation has limitations

If the advantages of a scientific methodology are to be presented, it must also be critically reflected. A simulation model is only as good as the underlying physical laws and input parameters, as well as the accurate representation of the conditions in operation or in testing.

The solution of a simulation is often a trade-off between detail and performance. According to the saying ''as simple as possible, but as complex as necessary''. In the various phases of a new development, this relation can also change. For example, in order to determine a suitable geometry or material, comparisons of designs are necessary for optimization, and the simpler the model, the faster the result and the more variations can be determined in the given time. For the best possible comparability, a close match with the conditions in the real test is essential. If the test and the simulation do not match, the reason is often a lack of conformity of the boundary conditions and the simulation is often declared to be wrong, because what can possibly be wrong with reality? This leads to an unfounded lack of acceptance of simulation methods and the given potential is not fully used.

5. Simulation is here to stay

As a conclusion, it can be said that simulations are an integral part of every development, but that the level of simulation is defined by the given circumstances. In a world that is constantly developing at such a rapid pace and always has new challenges in store, simulation is needed to keep up. Every manufacturer is obliged to get the very best out of its own products, and this includes, among many other aspects, the most economical and ecological production possible. Developing exclusively by means of "trial & error" cannot be argued in respect of time, economy & ecology.

Author:

Sascha Pazour is Simulation & Sales Engineer at PART Engineering GmbH, Bergisch Gladbach, Germany