The following components were examined on behalf of BRITA GmbH and are good examples of an optimization process towards less material usage and better quality. BRITA manufactures water filters, among other products, and is very committed to recycling.

This is a particularly good example of the influence that a sustainable approach can have on the entire product cycle. The declared goal was to achieve a significant reduction in weight and material in order to conserve resources and to produce even more effectively in the future.

How exactly does simulation help here?

Before optimizing a part´s structural integrity, a component must be examined in terms of its manufacturing process. For this reason, the design variants were first investigated for production purposes. Using suitable material data, injection molding simulations were carried out and the component was optimized in terms of its overall design and wall thicknesses. That way a proper production could be ensured without using too much material and thus keeping the energy consumption low and shorten the cycle time.

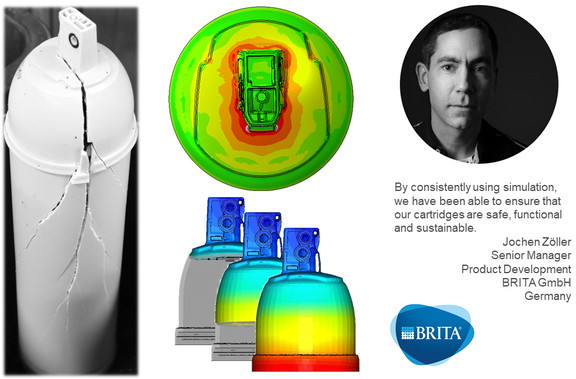

In addition, shrinkage and warpage were analyzed to be able to maintain the desired dimensions. In the case of BRITA's filter cartridges, this is very important, as they are friction-welded from individual components. To ensure that these welds remain intact under pressure, the relevant dimensions must be reliably maintained.

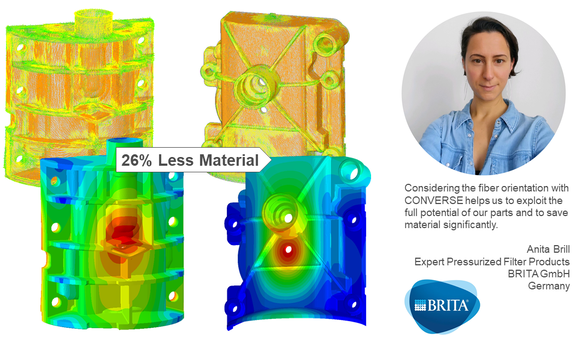

Another advantage of injection molding simulation is that for fiber-reinforced plastics, the exact position of the fibers is determined. Only through the correct consideration of the stiffening fibers and the resulting anisotropic properties, the mechanical simulation can be as close to reality as possible.

Using the software Converse from PART Engineering, these data were transferred into the structural simulation and the load cases of operating pressure and overpressure were investigated. The overpressure case is prescribed by legal standards and for safety reasons. While the overpressure corresponds to a one-time load, operating pressures are long-term loads or, if the pressure levels vary, can be considered as cyclic loading.

With S-Life Plastics from PART Engineering, these different types of loads can be easily assessed for plastic components and ensure both static strength and fatigue strength. In this way, BRITA's cartridges were optimized in terms of sustainability.

What do water filters have to do with sustainability?

When talking about sustainability, environmental and climate protection we cannot avoid the subject of plastics. Disposable bottles in particular are criticized because their production not only consumes resources and causes CO2 emissions, but their usage also generates plastic waste.

A better way would be drinking tap water instead of bottled water. Here filters can help to reduce limescale in the water and filter out substances that interfere with the taste of the drinking water. This saves resources, reduces CO2 emissions and also saves time and money.

Water filters can help reduce plastic waste. But why should that be more sustainable than plastic bottles when the water filters and cartridges are also made of plastic? The decisive difference lies in the service life and the total amount of water being consumed. The CO2 emissions from one liter of BRITA-filtered water is almost 25 times less than a liter of water from a bottle. In addition, BRITA GmbH is particularly concerned with the careful use of natural resources and waste avoidance. That's why the used cartridges are consistently recycled, thereby not only avoiding waste but also reducing the CO2 footprint of the water filters.

The cartridge materials used are mainly made from recyclable plastics. For example, the PURITY C cartridge is made of PP and glass fibers. On the inside, components and nonwoven fabrics are made of PP and PET. All these materials are recyclable.

Plastics are used for the BRITA Professional cartridges because they must be pressure-stable, the material must be legally approved for drinking water applications and should not be too heavy or too expensive. For these reasons, it is particularly important to design this component optimally.

By using simulation, this was achieved and, considering several components, up to 26% of material was saved. Thus, as little brand-new material as possible is brought into the cycle. Therefore, simulation will continue to play a decisive role in our new developments.

This will also help us to achieve our goals, such as the use of more recycled filler material in new cartridges than before and making our business activities carbon neutral through reduction and supporting sustainable compensation projects.

Authors:

Anita Brill, Expert Pressurized Filter Products, BRITA GmbH, Taunusstein, Germany

Jochen Zöller, Senior Manager, Product Development, BRITA GmbH, Taunusstein, Germany

Sascha Pazour, FEA Engineer & Software Sales, PART Engineering GmbH, Bergisch Gladbach, Germany