Material Modeling Easy and Accurate

What is MatScape?

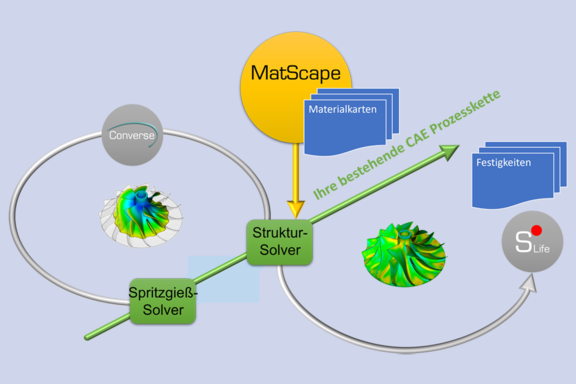

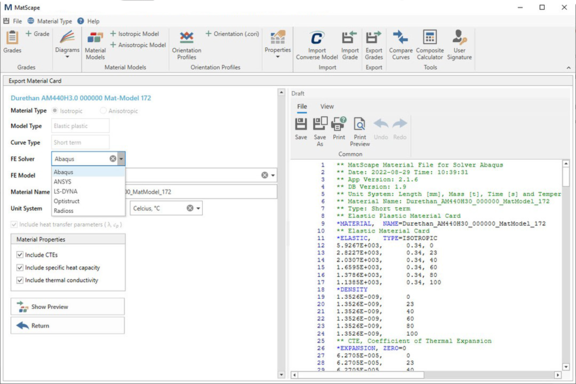

MatScape is the intelligent material modeling tool for the PART software suite. In interaction with Converse, MatScape provides material cards for proper FEM analysis. In interaction with S-Life, MatScape provides strength properties to evaluate the performed FEM analysis.

MatScape is an integral part of the PART software suite. In MatScape all material modeling technologies of the PART software suite are consolidated, which were located separately in previous versions of the individual software products. Thus, MatScape contains the "material intelligence" of the PART software suite.

MatScape is tailored to the specific needs of the computational engineer. MatScape is easy to use and is limited to the functionalities that are directly related to the creation of FE analysis data and the evaluation of simulation results. MatScape is not only material database but goes beyond.

The Problem

Missing High Quality Material Data

Commercial database systems, on the other hand, often allow the direct export of material cards, but are often unspecific because they contain many different material classes. Often, only simple standard models can be selected. The time and financial effort required to determine the necessary material data is sometimes considerable.

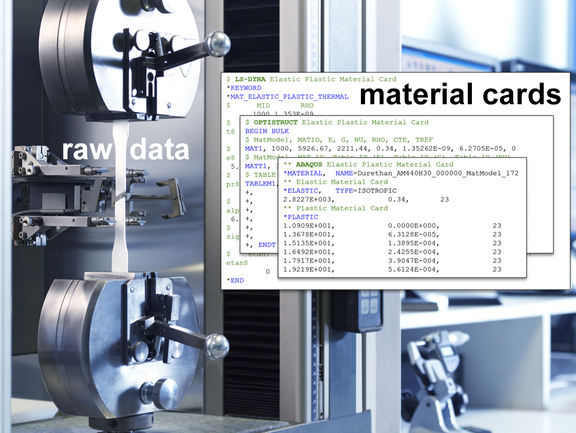

Missing Expertise

The creation of valid material cards based on raw material data, requires in many cases considerable specialized knowledge. This often leads to a gap in expertise because simulation is increasingly being democratized. What was previously the domain of materials or simulation experts is now to be carried out in parallel with design.

How does MatScape solve the problem?

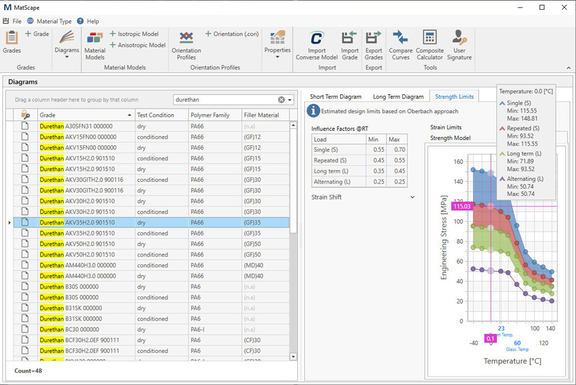

MatScape is your "material intelligence" in that the software provides ready-to-use material cards for a variety of trade grades for different FEM programs. In an intuitive way, material cards can also be created from incomplete raw material data. At the push of a button, design limits for the strength assessment of plastic components under various types of loads are determined.

Some features & functionalities

Plastics World

- High-quality manufacturer-authorized material data of various plastic raw material suppliers with more than 2000 stress-strain curves

- Own materials can be entered

- Generation of complete stress-strain curves from single point data (Young's modulus, yield stress & strain)

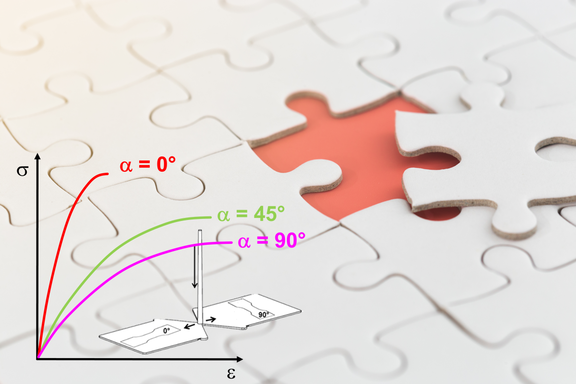

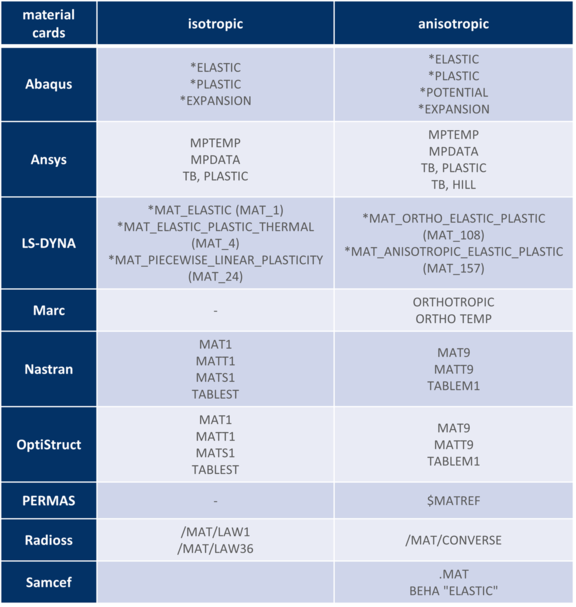

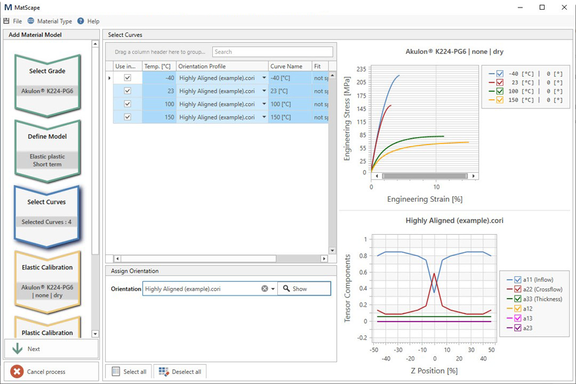

- Easy process-guided creation of anisotropic and isotropic elastic and elasto-plastic material cards for various FEM programs

- Curve editing tools and plausibility checks to achieve numerically valid material cards

- Predefined anisotropic and isotropic material cards for more than 150 plastic trade grades

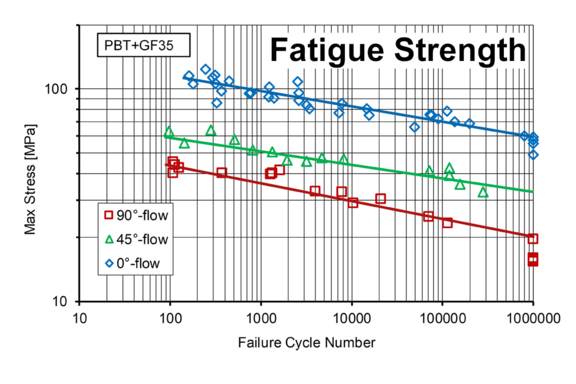

- Derivation of stress- and strain-based trade type specific static design limits for short-term single and multiple as well as long-term loads

- Derivation of trade grade specific S/N curves in the range of N=104 to 107 for stress ratios R=-1 and R=0

- Composite Calculator for the calculation of orientation-dependent elastic properties of short-fiber-reinforced plastic grades based on micromechanical models

- Intuitive polar diagram representation of anisotropic specimen properties of short fiber reinforced plastic grades

- Rights and revision management for created material cards for tracking and quality assurance

- Interface to Converse for creating part-specific anisotropic multiscale FE calculation models

- Interface to S-Life Plastics for static and cyclic strength assessment according to Stommel, Stojek, Korte [1].

Metals World

- Strength properties for more than 1600 material grades (steel, aluminum, cast iron) according to the material tables of the FKM guideline [2].

- Own materials can be entered

- Interface to S-Life FKM to perform static and cyclic strength assessment according to the FKM guideline

[1] M. Stommel, M. Stojek, und W. Korte, FEM zur Berechnung von Kunststoff- und Elastomerbauteilen, 2. Aufl. München: Carl Hanser Verlag, 2018.

[2] Analytical Strength Assessment of Components in Mechanical Engineering, FKM Guideline, 7th revised edition Frankfurt, Germany : Forschungskuratorium Maschinenbau, VDMA Verlag, 2020.

Benefit

The usefulness of an FEM analysis depends to a large extent on the quality of the material data and the material cards derived from it. MatScape helps you to easily create high quality material cards.

MatScape reduces

- Costs for material testing, since valid material cards are already included or these can also be created from incomplete existing material data.

- Costs for simulation execution (CPU time, license draw), since only optimized solver-own material models are used

- Development time, since reliable assessments can be made based on simulation results already in early development stages, when time-consuming material tests are not yet justifiable.

- Part and rework costs, since over- or under-dimensioning can be avoided through more accurate simulation results.

MatScape increases

- Accuracy of simulation results, as important material characteristics (e.g., anisotropy) can be captured.

- Reliability of the simulation results, since material cards are generated based on proper, standardized procedures

- Confidence in the simulation results, since open data handling (human-readable material cards) makes the applied procedures understandable and verifiable.

Users say

Getting material data for simulation is often a challenge. With the help of MatScape, we can create meaningful material cards and evaluate component behavior even when the data is sparse.

We use MatScape as a database for our materials. The easy handling and useful functions have particularly convinced us here. Material cards can be created almost at the push of a button.

For our simulations, we use different material models. Also, a strength evaluation is required. MatScape provides the required functionalities for this, which gives us a great advantage.

Get MatScape

Please contact us for an individual quote without obligation

MatScape can also be used integrated with Converse, S-Life FKM and S-Life Plastics through the Altair Partner Alliance.