Strength Assessment of Plastic Parts

What is S-Life Plastics?

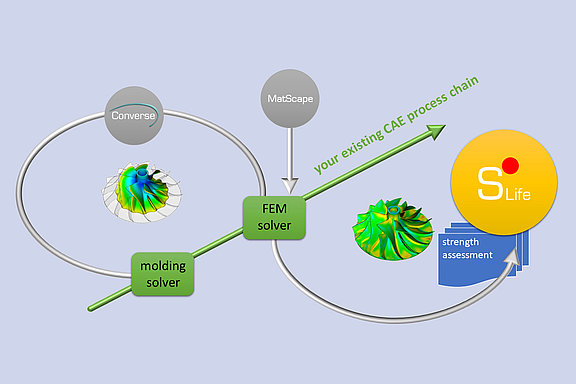

S-Life Plastics is the strength assessment software within the PART software suite for plastic components made out of unreinforced or short-fiber-reinforced thermoplastic materials. Results from a structural simulation are automatically assessed. The software is used as a post-processor.

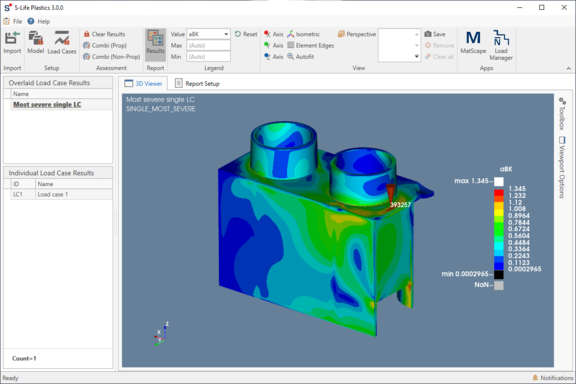

With S-Life Plastics, mechanical stresses from FEM simulations are processed in a way so that an evaluation of static strength and fatigue strength is possible. As a result, among other things, the static and cyclic utilization ratios of the component are displayed as a contour plot.

The Problem

Missing standardized procedures

The correct assessment of simulation results determines to a large extent the benefit of the simulation in the first place. With regard to the evaluation of the mechanical strength of components, it is regularly unclear how this is to be carried out. This is particularly the case for plastic parts. Lack of application of suitable procedures leads to uncertainty or, in the worst case, incorrect assessment results.

Missing design limits

For plastics in particular, databases generally do not contain any mechanical design limits. This applies for static and especially for cyclic loading. A common procedure is to use a static strength limit as a substitute, e.g. the breaking or yield stress or strain. This is only justified in specific cases of the loading situation. For example, the actual application may involve repeated, long-term or even cyclical load. A distinction must also be made between relaxation and creep load cases, the design limits are different in each case.

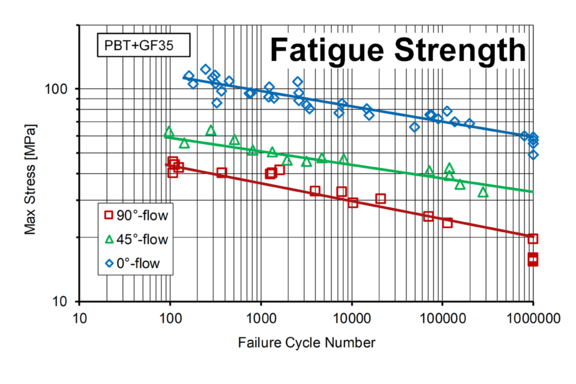

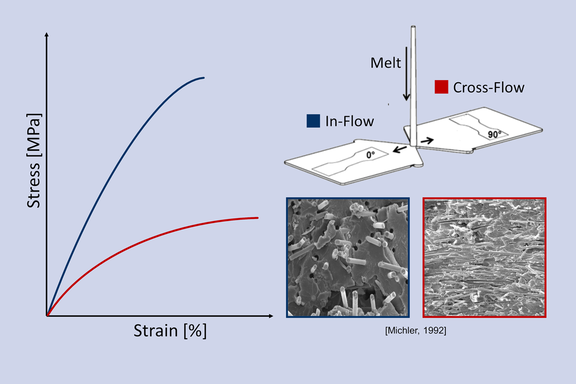

Fiber-reinforced plastics are challenging

Highly loaded engineering components are often made from short-fiber-reinforced plastics. This leads to a directional dependence not only of the stiffness but also of the strength properties. In addition to the problem of the availability of such properties, there is also the problem of converting the calculated anisotropic stress state to a suitable equivalent stress or strain in order to conduct a strength assessment.

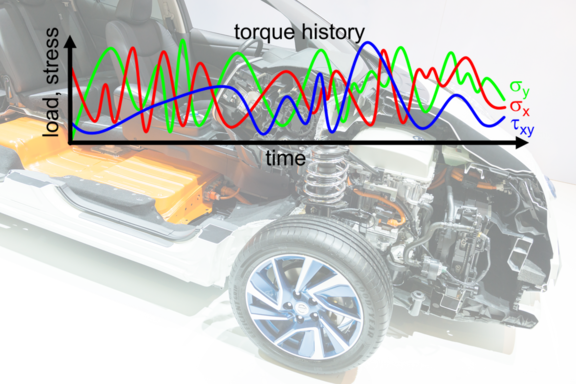

Time-varying loads are difficult to take into account

In general, components are subject to multiple independent time-varying loads. This regularly leads to the problem of how to evaluate the resulting stresses in terms of their damage potential. Also, the critical load case combination as such is often unknown. The solution of these problems is algorithmically complex and usually only possible with computer assistance.

How does S-Life Plastics solve the problem?

Based on the simplified strength assessment methods for plastic components described in [1], Chapter 6, a simplified static strength assessment and fatigue strength assessment is carried out in S-Life Plastics. A more comprehensive assessment for static loading is available for injection-molded short-fiber-reinforced plastics.The assessment is carried out almost at the push of a button. For this purpose, S-Life Plastics requires isotropic or anisotropic local stresses from FEM analyses, depending on the assessment method used.

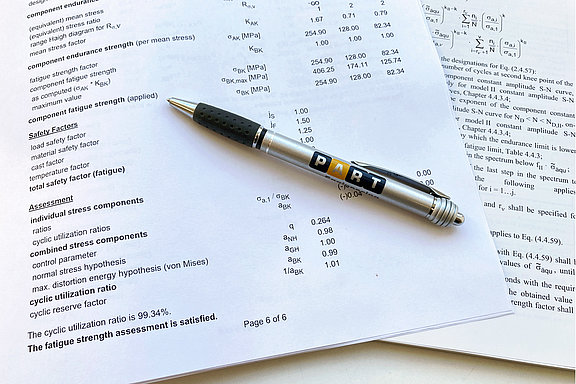

S-Life Plastics ensures that the methods used are technically correct. Unambiguous, user-independent results are achieved. In addition, S-Life Plastics provides a detailed assessment report for the critical hot spots investigated. A plausibility check and communication of the results is thus easily possible.In the future, the VDI guideline 2016 "Strength assessment of components made of thermoplastics - Strength assessment against static loads" will also be available in S-Life Plastics. For the first time, this guideline provides a standard that reflects the state of the art for the strength assessment of plastic components. This guideline is currently still in the draft phase.

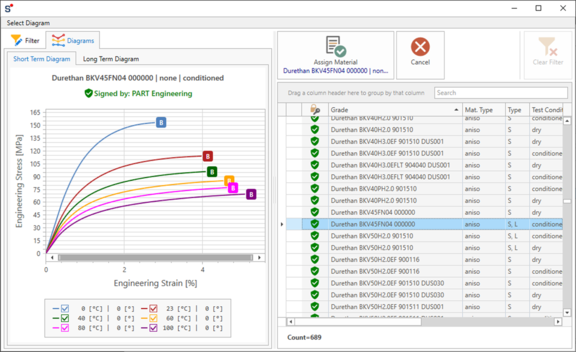

The S-Life Plastics material database contains strength properties of widely used plastics grades. Own grades can be entered. The concept of synthetic S-N curves used in the simplified fatigue strength assessment automatically determines the required fatigue strength properties for the endurance limit or finite life strength from static strengths properties. S-Life Plastics thus enables fatigue strength assessments to be carried out without time-consuming experimental determination or research of fatigue strength properties.

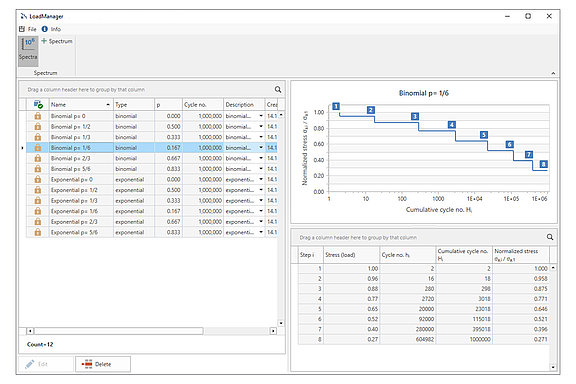

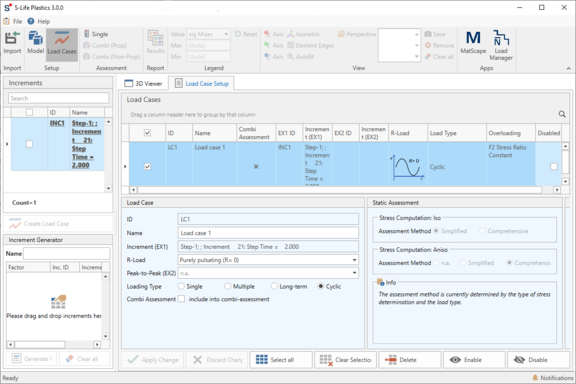

Time-varying loads with multi-level amplitudes are taken into account with S-Life Plastics in accordance with the Miner damage accumulation approach. For this purpose, S-Life Plastics offers a selection of standard load spectra via the integrated load-manager. Own spectra can be added easily. S-Life Plastics also allows fatigue strength asessments to be carried out for independently acting multi-axial non-proportional loads. The load-combinator integrated in S-Life Plastics can be used to determine the locally most unfavorable load combination for several superimposed loads.

Some features & functionalities

- Simplified static strength assessment and fatigue strength assessment according to [1], chapter 6.

- Comprehensive static anisotropic strength assessment for short-fiber-reinforced plastics

- Material database with selection of plastics grades from renowned suppliers, own materials can be entered

- Load-manager with integrated standard spectra (binomial and exponential), own spectra can be entered

- Load-combinator for stress preprocessing (addition, subtraction, multiplication) including determination of critical load combinations for multiple simultaneous loads

- Handling of non-proportional multi-axial stresses according to FKM guideline

- Display of static and cyclic load utilization ratios on the component as a 3D contour plot

- Comprehensive reporting of the assessment results per selected node in pdf format

- 3D viewer for displaying and evaluating results

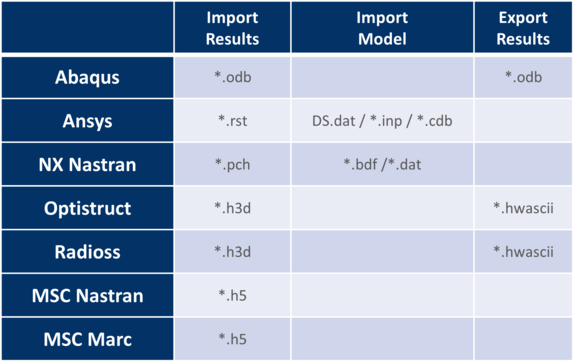

- Interfaces to commercially available structural simulation programs. Details can be found in the table on the right.

S-Life Plastics reduces

- Costs for material testing, as strength properties are either already included or are determined automatically from comparatively inexpensive static tests, e.g. long-term or cyclic strengths properties

- Development time, since the simple automated application eliminates laborious manual assessments

- Errors, since the automated procedure avoids incorrect settings and misinterpretations to the greatest possible extent

Users say

Fresenius Medical Care’s dialysis machines contain several plastic components, that have to withstand various mechanical loads. For health reasons a breakdown or malfunction is not an option. Using PART Engineering Software helps to analyze the parts strength and to increase the confidence in the machines.

S-Life Plastics enables our plastic parts to be designed in a time-efficient and standardized manner with regard to static and cyclical strength. This increases the safety of our products and shortens their development times.

S-Life Plastics enables the engineers to perform a material data-based strength assessment to reach a high level of simulation accuracy and allow more reliable lifetime predictions of parts.

The operating load or legal requirement vs. which design must be carried out varies depending on the application. In questions of safety, it is often a matter of short-term misuse loads, but in questions of quality, it is more a matter of long-term or cyclical behavior. These questions can ultimately be answered with S-Life Plastics.

Get S-Life Plastics

Please contact us for an individual quote without obligation

S-Life Plastics can also be accessed through the Altair Partner Alliance, learn more here.