The traditional company BERG TECTOOL GmbH from Cologne, Germany, develops and produces various construction tools and power tools for the building trade and stands for quality and competence in a wide range of trades for many years. The products are constantly being developed further to be able to react quickly to the special features in this market.

Quality

Quality, reliability and customer-specific flexibility are essential characteristics for BERG TECTOOL GmbH and the simulation and cooperation with PART Engineering are means to achieve them.

Despite the highest quality demands, even a BERG tool can sometimes run down during hard work on the construction site. In the event of a warranty claim, a repair will be carried out free of charge or, if necessary, a replacement will be provided free of charge. However, it is best for both the customer and the manufacturer to avoid this as far as possible and therefore to pay particular attention to pre-development.

Every hour of time invested here pays off, because solving the problems afterwards in production or even in the field is much more costly and satisfies neither the customer nor the manufacturer.

Sustainability

In addition, development also helps with the right choice of materials for new tools. When developing new products, care is always taken to ensure that all relevant environmental standards are observed and that flawless and harmless products are delivered. In this way, the promise can also be made to dispose of old equipment in an environmentally friendly manner after it has been returned by recycling the materials the correct way.

The New Handheld Electric Mixer

One of the latest development projects is the BERG MX 19 electric mixer/agitator. It impresses with top quality and an extraordinary design. Powerful, lightweight, versatile and designed for daily use. The 1850 watt motor with power electronics brings constant power when mixing and the high-torque 2-speed gearbox ensures a long service life. Sturdy steel corners in the handle also protect the machine from damage during daily use.

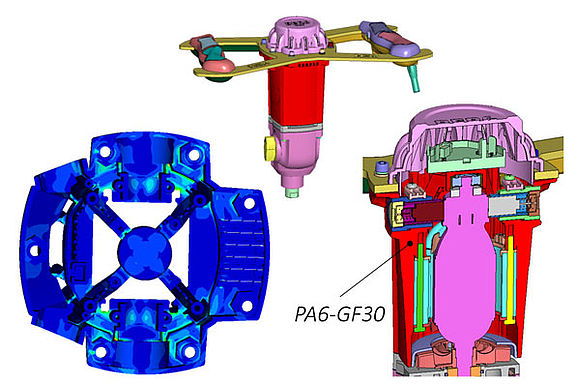

Among other things, these qualities were achieved using simulation. The power from the 1850 watt motor must be transmitted and withstood perfectly by all components of the device. This applies to electronic components, as well as to components subjected to mechanical or thermal stress.

Simulation Potential

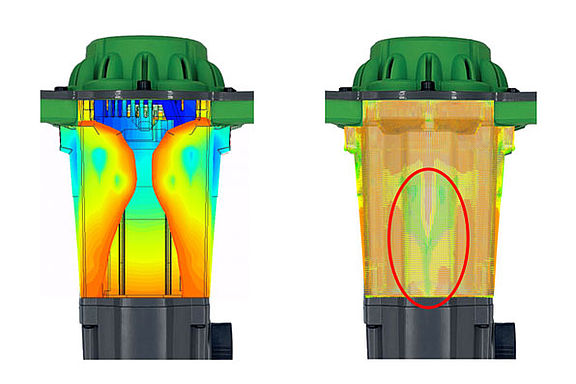

Torque plays a major role in this device. In this specific case, the housing was simulated under corresponding loads. By means of a structural simulation, it is possible to quickly find the areas that require further improvement or, conversely, the areas where material can be saved.

Also crucial for construction tools and simulatable in this way is the temperature development and temperature distribution during use.

The production of a component can also be simulated. On one hand to uncover manufacturability and associated problems at an early stage, or to take manufacturing influences into account in the mechanical assessment.

An injection molding simulation was carried out for the housing. The results available in this way (e.g. orientations and weld lines) can be transferred to the structural simulation using the Converse software.

Life Span

Construction machines work very hard and should be able to withstand loads over a long period of time. All the previously mentioned influences such as forces, moments, temperatures or weld lines can significantly affect the service life.

Often, small measures such as increasing the radii or an additional rib can significantly increase the service life.

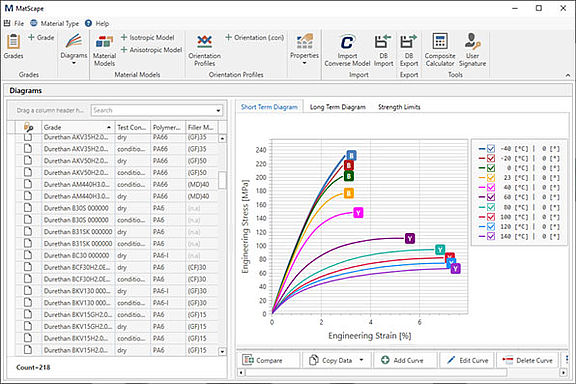

The strengths of different materials play a decisive role here. For plastics and metals, MatScape helps to make the right choice of material and the associated strength.

The assessment of a possible failure can then be carried out using suitable software for these two material groups. The operating load or legal requirement against which design must be carried out varies depending on the application. In questions of safety, it is often a matter of short-term misuse loads, but in questions of quality, it is more a matter of long-term or cyclical behavior.

These questions can ultimately be answered with S-Life FKM (for metals) and Plastics (for plastics).

For BERG's existing and new construction tools, quality and customer satisfaction will continue to be the drivers for holistic product development, including simulation wherever possible.

Author: Fabian Berg, Managing Director BERG TECTOOL GmbH

Co-author: Sascha Pazour, Simulation and Sales Engineer, PART Engineering GmbH